ZBS FLOOR PAINT

Product Code :

CATEGORY : Floor Painting

Subcategory : ZBS ROAD AND FLOOR COATING

Impact Resistant, Cellulosic and easy to apply, Floor Paint

Single component. Ready to use. Easy to apply, fast drying due to its cellulosic structure, Flooring, Coloring and Protection Paint

DESCRIPTION: Methyl Methacrylate Reactive resin based, Fast drying due to its cellulosic components. Thanks to its specially improved chemical structure, its resistance to external conditions, impact, friction and wear is maximum . Without requiring additional labor, EASY APPLICABLE , highly economical compared to epoxy systems. Single component. Very strong. Long lasting. It is a floor coating, coloring and protection paint.

NOTE: Do not compare with some of our competitors' products, which are Water Based (Examine with water), and the bucket price is suitable, with a very high consumption of m2 under the name of Floor Paint. Because, they are not equivalent to our ZBS Floor Paint product.

USAGE AREA AND FEATURES:

All kinds of Asphalt, Concrete, Screed, Helicopter Concrete, Concrete with Surface Hardener, Ceramic, Palelian, Paving stone, Natural stone, Brick stone, Travertine, Epoxy etc. It can be easily applied on floors with a roller, brush or pistol. With high flexibility, excellent adhesion, abrasion and friction resistance, this product is never affected by UV rays and Meteorological conditions. It covers fine capillary cracks in the ground. It is absolutely waterproof under the applied surface. It has the feature of fast drying. You can open the application area to pedestrian or vehicle traffic within 1-4 hours. (Ambient temperature 20-30 Co) Does not dust and slide. It provides high resistance against salt water and chemicals. It does not dust and slide on the applied surface. Factory floors, Aircraft Hangars, Housing, Open and closed car parks or terraces of workplaces and shopping malls, car wash and carpet washing facilities. School Fields, Sports Fields, Auto Industry Floors, Fuel Station Floors, Warehouse and Warehouse Floors, Floors of Logistics Areas, Pedestrian and Vehicle traffic etc. It has been specially developed for covering, protecting, coloring and marking the floors of the areas. After curing, it is resistant to the impact and friction effects of all types of wheeled vehicles and pedestrian traffic. It has been developed and improved at maximum values against abrasions and impacts that may arise from the use of forklift trucks such as Forklift and Pallet truck in Warehouse, Factory and Logistics areas. Fuel Stations floors, Warehouse and Warehouse Floors, Grounds of logistics areas, etc. exposed to Pedestrian and Vehicle traffic. It has been specially developed for covering, protecting, coloring and marking the floors of the areas. After curing, it is resistant to the impact and friction effects of all types of wheeled vehicles and pedestrian traffic. It has been developed and improved at maximum values against abrasions and impacts that may arise from the use of forklift trucks such as Forklift and Pallet truck in Warehouse, Factory and Logistics areas. Fuel Stations floors, Warehouse and Warehouse Floors, Grounds of logistics areas, etc. exposed to Pedestrian and Vehicle traffic. It has been specially developed for covering, protecting, coloring and marking the floors of the areas. After curing, it is resistant to the impact and friction effects of all types of wheeled vehicles and pedestrian traffic. It has been developed and improved at maximum values against abrasions and impacts that may arise from the use of forklift trucks such as Forklift and Pallet truck in Warehouse, Factory and Logistics areas. it is resistant to the impact and friction effects of all types of wheeled vehicles and pedestrian traffic. It has been developed and improved at maximum values against abrasions and impacts that may arise from the use of forklift trucks such as Forklift and Pallet truck in Warehouse, Factory and Logistics areas. it is resistant to the impact and friction effects of all types of wheeled vehicles and pedestrian traffic. It has been developed and improved at maximum values against abrasions and impacts that may arise from the use of forklift trucks such as Forklift and Pallet truck in Warehouse, Factory and Logistics areas.

SURFACE PREPARATION

Before applying ZBS Floor Paint , it is necessary to make sure that the floor is absolutely dry, clean and self- supporting . Floor cleaning should be done by sweeping as much as possible or by removing air and dust from dust and particles. Unless absolutely necessary, washing with water should be avoided. Because even if the water on the surface dries after washing, it will seriously threaten the adherence (adhesion) capability of the paint in the future, especially since the moisture penetrated into the concrete dries later and cannot be noticed. If there are oil or similar petroleum-based stains or areas on the floor, these areas should be cleaned using cellulosic thinner. Synthetic Thinner should never be used.

If you have a dense dusting floor that constantly dries from the bottom as it is swept or cleaned. First of all, you should apply our ZBS Anti-Dust product to the floor in double layers. Since the density (viscosity) of this product is very low, it is quickly absorbed (penetration) by the ground, realized on cement based surfaces. While doing this absorption, it absorbs the dust on the surface and prevents it from coming to the surface as well as trapping new dust particles that may come from the ground. It acts as a kind of barrier on the ground. May be applied over so , ZBS floor paint ideal product for bonding (adhesion) to saturate the surface as it forms the basis ZBS floor paint It also has a very positive effect on its consumption. By clicking the link on the side, you can access the technical data and usage details of our ZBS Anti-Dust product.

PLEASE CLICK FOR ZBS ANTI-POWDER

In addition, if there are surface deformations such as cracks, clefts and broken parts that we frequently encounter on cement based floors (Concrete, Helicopter Concrete, Screed etc.), then you can make the necessary repairs and surface corrections with our ZBS 2K Floor Repair Putty product. This product is offered in 15 kg powder and 4 kg liquid, in 19 kg packages, with double components. Approximately 30 min. You can open the surface you are repairing very quickly, as it provides hardening in it. With the ZBS 2K Repair Paste , you will fill the openings on the floor and get a flat surface . You will have significantly reduced the consumption of. Thus, more area will be applied with less paint. You can reach the technical data and usage details of our ZBS 2K Floor Repair Putty product by clicking the link on the side . PLEASE CLICK FOR ZBS 2K FLOOR REPAIRING PASTE .

Also, if you are going to apply on glossy / matt and smooth (non-porous) surfaces such as Ceramic, Granite, Marble etc., you should use the " Extra " class of our ZBS Floor Paint product . Before application, you should definitely use our one layer ZBS Glossy Surface Transition Primer product on a dry and clean surface . Because, adherence (adhesion) problem always occurs on bright and smooth surfaces. Our ZBS Glossy Surface Transition Primer product can be applied on this type of surface by forming pores and teeth, and ZBS Extra Ground Paint .It provides suitable adhesion and adhesion ground. Thus, you can use it smoothly on shiny and smooth surfaces such as Ceramic, Granite, Marble etc. However, it should not be forgotten that despite all these measures, the pattern and model differences of the manufacturing companies, the firing times of ceramics in manufacturing, the adhesion to the primer and paint floor in such a case due to the fact that it is a transparent lacquered texture on the surfaces of some ceramics, granite, marble, etc. (adherence) may have problems. In order not to be a victim of this situation, we recommend you to experiment by practicing in a small place that is not visible.

If you have a glossy and cured concrete surface known as polished concrete, our ZBS Glossy Surface Transition Primer cannot be sufficient on such a surface . Instead, as a first treatment, you should wipe over the glossy cured concrete surface with ZBS Cellulosic Thinner and remove the cured glossy texture. You can reach the technical data and usage details of our ZBS Glossy Surface Transition Primer product by clicking the link on the side .

PLEASE CLICK FOR ZBS GLOSSY SURFACE PASSING LINER

In addition, our ZBS Floor Paint product has a waterproof feature. However, if there is a serious water insulation problem such as water flow or water leakage from the surface you will be applying, in this case, ZBS Floor Paint should be applied to the floor, Concrete, screed and cement based etc. before applying . Thanks to its fine viscosity, ZBS WaterCut BN Silicone Polymer additive, which we developed especially for floors , fill the pores and it will be very useful to use our White transparent, Ground Waterproofing product, which penetrates deep into the concrete floor due to its crystalline structure. You can easily apply the same product for waterproofing on concrete floors of roofs, roofs, roofs and balconies that can be climbed. You can reach the technical data and usage details of our ZBS WaterCut BN product by clicking the link on the side . PLEASE CLICK FOR ZBS WaterCut BN .

If your water leakage problem is not on the concrete surface, but on a ceramic, granite, marble, palerdian etc. surface, you can use our ZBS Shock Guard product in double layers. Since ZBS Shock Guard is transparent (transparent), it provides a vibrant gloss to the surface without covering the decorative structure and visual effect of your ceramics, granite, marble, paledian, etc., and provides a waterproofing effect. Thanks to its thin structure, it progresses rapidly between the capillary cracks and joints on the surface, clings to the floor from the inside and is absorbed. Thanks to its cellulosic structure, it is not affected by the harmful UV effect of the sun and meteorological conditions. It does not constitute an obstacle for the traffic on it. Does not make scrolling and dusting. If you want, when you want to color the floor, ZBS Floor Paint You can apply. You can access the technical data and usage details of our ZBS Shock Guard product by clicking the link on the side . PLEASE CLICK FOR ZBS Shock Guard.

METHOD OF APPLICATION :

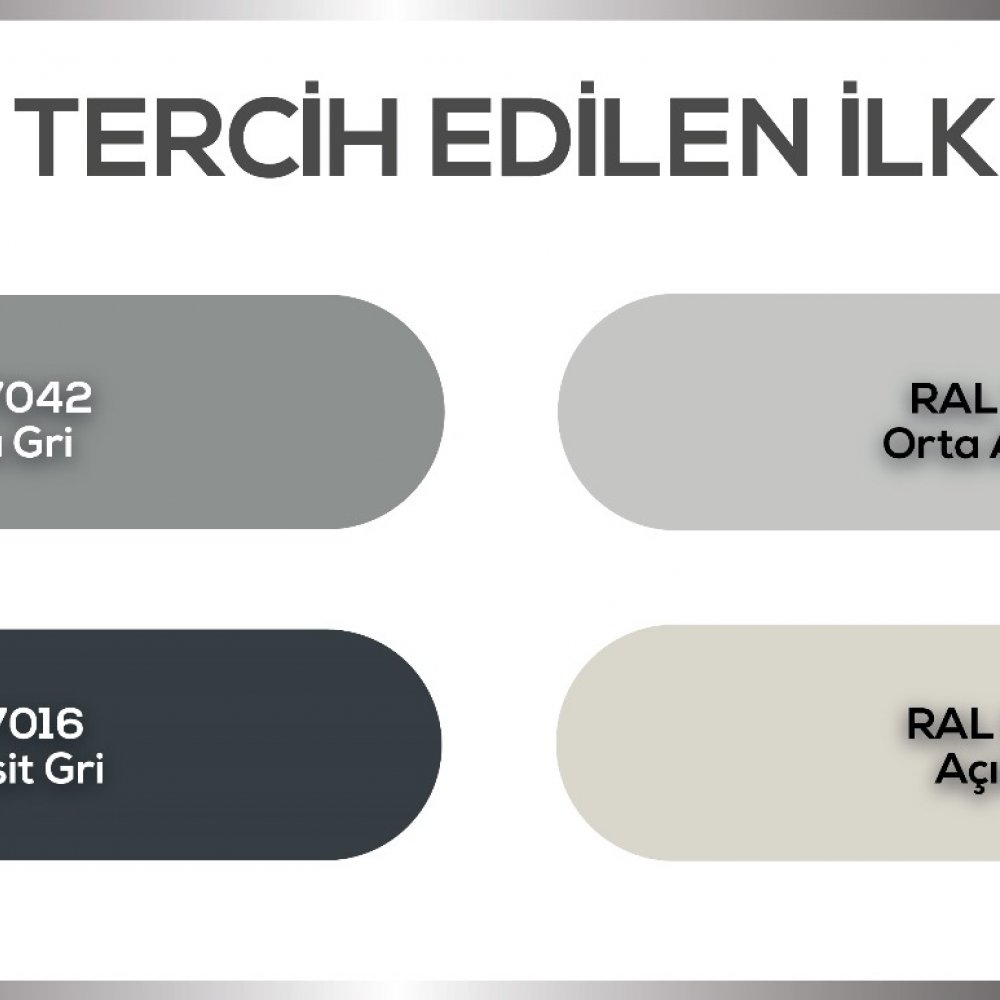

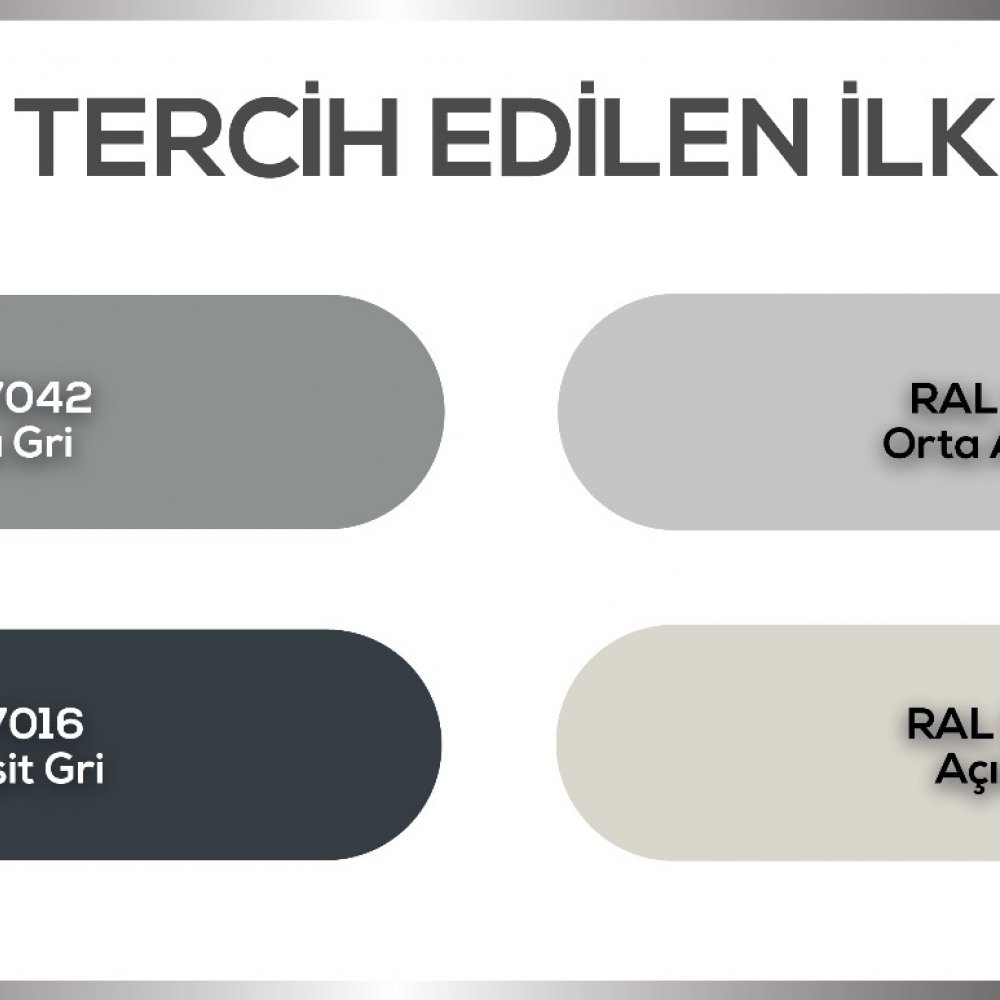

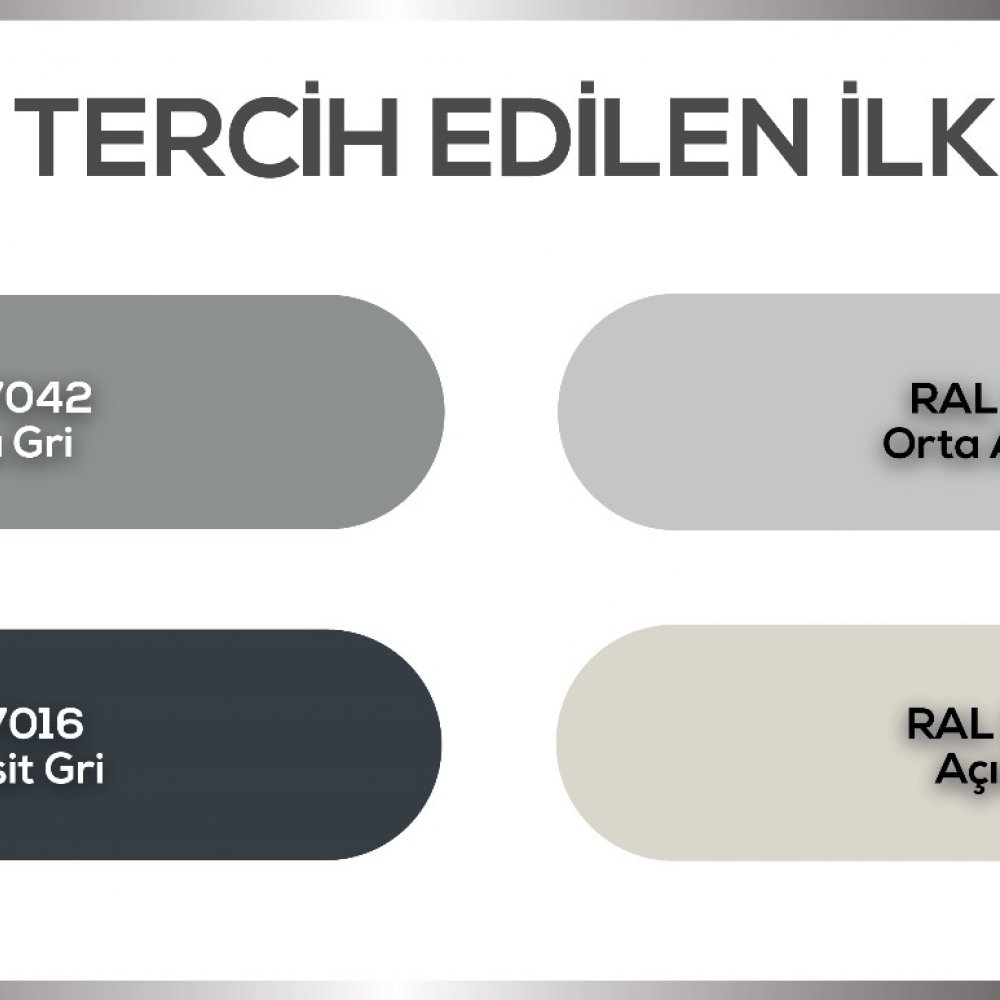

Since our product will be delivered to you with a single component and ready, you can easily apply it yourself. During paint application, rainy or extremely hot (dry) environments should be avoided. It should be applied in hours that are not directly exposed to the sun's rays as much as possible. Application should be done under ambient temperature of 20-30 ° C. Before the application, you should thin the product with the addition of 1 kg Cellulosic Thinner in 1 bucket of 20 kg. The product should be mixed for a long time until it is homogenously sure of dispersion. Mixing process is very healthy with a low speed drill. Dry (moisture-free), cleanly prepared, free from all kinds of dust and external threats, in 2 layers with roller brush or spray, ZBS Floor Paint It is applied. It is necessary to wait for an average of 1-4 hours (in ventilated, 20-30 Co environments) between coats. With our 299 color options, we can produce the colors you want without any difference between the colors. You can reach the common color chart of our products by clicking the link on the side.

To the attention of our consumers: Our ZBS Floor Paint product is very economical compared to epoxy systems. You can also open the application area to pedestrian and / or vehicle traffic without waiting too long. When comparing with epoxy systems, you should compare with solvent-free epoxies. Because the epoxy systems used for the floor are solvent-free epoxies. Some of our consumers compare solvent epoxies with affordable prices. This type of solvent epoxies are not used on the ground. They are suitable for metal, they are mostly preferred in iron and steel industry. When applied to the floor, they get lifted over time and create a loss of adherence. ZBS Boya ve Kimya San.Tic.Ltd.Şti. As, we also produce epoxy paints with and without solvent. You can review our products from the links on the side. ZBS Solvent Epoxy Paint ZBS Solvent Free Epoxy Paint

ZBS Solvent Free Epoxy Paint

PLEASE CLICK FOR ZBS COLOR CHART.

THINNING:

Since the product's cover will remain open before and during the application, the product may become dense (thick) due to the fact that some of the cellulose in the body is mixed with the air. Consequently, it may be difficult for the roll to slide on the ground. In order to eliminate this, ZBS Cellulosic Floor Paint Thinner can be thinned up to 5% (1 kg in 20 kg 1 bucket) in Brush or roller applications and up to 10% in Pistol (gun) applications in order to gain the density lost by the product . You can reach the technical data and usage details of our ZBS Cellulosic Floor Paint Thinner product by clicking the link on the side . PLEASE CLICK FOR ZBS CELLULOSIC FLOOR PAINT TINER.

PRESENTATION VIDEO OF ZBS FLOOR PAINT PRODUCT:

PRESENTATION VIDEO OF ZBS FLOOR PAINT PRODUCT:

CONSUMER PROMOTION VIDEO: "HOW DO I APPLY SELF" BY PAYING ZBS FLOOR PAINTING:

THE MOST HEAVY AND DIFFICULT DIRTS, THE SINGLE FLOOR PAINT ZBS FLOOR PAINT, CLOSING ON THE FLOORS OF THE AUTO REPAIRS IN A SINGLE FLOOR

IMPORTANT NOTE :

If you wish, at least 1-4 hours after the paint application, ZBS Floor Guard (Floor Protector) can be applied as a single layer by roller or spraying, in order to ensure late dirt and easy cleaning, to create maximum resistance against impacts, friction and abrasion and to extend the life of the application much more . ) you can apply our product. Since this product is transparent (transparent), it provides full protection to the floor and paint application by creating a film layer on the surface without closing the underlying image. Waterproof. It allows the floor to look brighter, decorative, easier to clean and difficult to stain. If there is water leakage on your surfaces such as ceramic, granite, paledian, etc., you can provide complete water isolation effect with our ZBS Transparent Guard product. It never makes swiping and dusting. ZBS Ground Guard You can open your floor to pedestrian and / or vehicle traffic after a minimum (average) 4 hours of application. It is now ready for you to use. You can access the technical data, images, usage videos and usage details of our ZBS Floor Guard product by clicking the link on the side . PLEASE CLICK FOR ZBS GROUND GUARD.

To be more understandable, below is the application video of our ZBS Ground Guard product. Please watch.

APPLICATION VIDEO OF OUR ZBS GROUND GUARD PRODUCT

ATTENTION PLEASE......

ATTENTION PLEASE......

WHEN APPLICATION IN INDOOR AREAS, THE AREA MUST BE GOOD VENTILATED, USED A MASK AND DOES NOT STAY IN THE LONG TIME.

ATTENTION PLEASE......

ATTENTION PLEASE......

In order to be more descriptive and understandable, you can click on the link for our question-answer form that we have compiled from your questions. We are absolutely sure that you will find a relevant question on your background. Therefore, we strongly recommend that you review our link and be informed. FREQUENTLY ASKED QUESTIONS

| COLOR | 299 pcs. Including the Color option, PLEASE CLICK TO CARD  |

| VISCOSITY | 84 - 88 KU (according to seasonal conditions) |

| DENSITY | 1,5700 g / cm3 |

| KMM (%) | 60 |

| DRYING TIME | Touch drying completes 25 minutes, 60-240 minutes. also hardens. (At 22-30 ° C, sunny, in the circus area) |

| APPLICATION TOOLS | Roller, brush, compressor |

| CONSUMPTION I (THEORETICAL) | 0,300 - 0,400 g / m² (1 bucket of 20 kg is applied on a double layer with an average area of 50-60 m2.) |

| CONSUMPTION II (THEORY) | 1,0 -1,5 kgr / m² (500 micron dry film thickness, with special road marking machine on concrete and asphalt floors) |

| PACKAGING SHAPE |

20 KG. / METAL BUCKET (COOPER WITH CIRCLE LOCKING) |

| THINNING | 5% -10% ZBS CELLULOSIC FLOOR PAINT THINNER ACCORDING TO APPLICATION MATERIAL |

| SHELF LIFE | 5 YEARS IN ORIGINAL PACKAGING |

|

DANGER WARNINGS |

R10: Keep out of the reach of children. R20 / 22: Harmful by inhalation and if swallowed. R52 / 53: Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic environment. R65: Harmful if swallowed, may cause lung damage. |

|

SAFETY NOTICES |

S7: Keep in tightly closed container. S24 / 25: Avoid contact with eyes and skin S28: In case of contact with skin, wash immediately with plenty of water. S29: Do not empty into drains. S46: If swallowed, seek medical advice immediately and show the container or label |

APPLICATION VIDEO OF ZBS FLOOR PAINT PRODUCT WITH COMPRESSOR ON CERAMIC FLOOR (Üsküdar-Çekmeköy Metro line - Çakmak Station platform floors)

APPLICATION VIDEO OF ZBS FLOOR PAINT PRODUCT WITH ROLLER ON CERAMIC FLOOR (Üsküdar-Çekmeköy Metro line - Çakmak Station platform floors)

APPLICATION VIDEO OF ZBS FLOOR PAINT PRODUCT ON RUN, DISABLED ROAD FLOOR (Üsküdar-Çekmeköy Metro line-Çakmak Station platforms)

ZBS FLOOR PAINT PRODUCT APPLICATION VIDEO ON RUN, ASPHALT FLOOR (Otağ Residences open car park / Beykoz)

ZBS FLOOR PAINT PRODUCT APPLICATION VIDEO ON NATURAL STONE (Gold Country Recreation Area-Maltepe)

APPLICATION VIDEO OF ZBS FLOOR PAINT PRODUCT ON CONCRETE FLOOR

APPLICATION VIDEO OF ZBS FLOOR PAINT PRODUCT ON TRAVERTINE FLOOR

ZBS Floor Paint Application of our product on the closed production area, concrete surface, wet volumes.

ZBS Floor Paint Application of our product in open area, on concrete floor (cafe open to pedestrian traffic)

ZBS Floor Paint Our product is applied on the patterned Asphalt Floor in the open area (Otağ Houses / Beykoz)